The world is facing a waste crisis, and ceramic waste is becoming an increasingly pressing issue. Even though this material is demanded for its durability, it is not biodegradable. Thus, it poses a serious environmental threat by lingering in landfills for centuries. The problem has intensified with the rising demand for ceramic products.

However, one visionary designer recognized an opportunity to revolutionize the market with his unique approach. Shashank Nimkar, who has dedicated the past few years to this mission.

In 2021, he launched his startup, Earth Tatva, which converts ceramic waste into a multifunctional material. Such that, this mix is embraced by artists, architects, and designers alike.

Early Life and Background

After completing his undergraduate in animation film design from Symbiosis Institute of Design in Pune, Shashank worked as a freelancer in the advertising industry for several years.

Later, in his Master’s in Industrial Design at NID, Ahmedabad, he chose glass design and ceramics. In 2017, while visiting Khurja (UP’s ceramic manufacturing hub), he found his Eureka moment, or shall I say, shocking moment.

While wandering through the streets, exploring various factories, he was struck by a troubling sight: ceramic waste strewn across the landscape. After talking with several industrialists, he found that ceramics are not biodegradable. This waste, it seems, will persist long after we have departed.

NID Paved the Way to Earth Tatva

“Why do we, as designers, exist?”

This existential question struck Shashank as he confronted mountains of ceramic waste.

With new seasons, new colors, collections, and shapes of ceramic waste are added to the mountains.

Shashank realized that he needed to explore the world of ceramic waste, but he wasn’t aware that this would lead to the creation of Earth Tatva.

His master’s project at NID proved helpful for addressing this issue. After devoting considerable time to research work, he discovered a pilot project from late 1999 in Japan. Under this project, up to 50% of recycled ceramic content was used in making new things.

It gave him the breakthrough as to what should be done with ceramic waste.

His discovery: Turn ceramic waste into a valuable resource.

Challenges and Solutions

However, his mission extended beyond merely recycling ceramics; he also encountered significant technical challenges.

The major challenge was to find the appropriate binder for the ceramic content.

Mostly, cement or resin was considered because they were not sustainable options in the long run. It is possible they separate themselves from the ceramic when disposed of.

So, he started looking for an option that was durable but recyclable. Solution: CLAY.

Yes, he found that clay is a natural binder.

By the end of 2018, Shashank had made significant strides in his project research, successfully finding a method to blend recycled ceramic waste with his unique clay binder. Then was the time to try the slip casting process. It is a technique that utilizes a liquid blend of recycled ceramic and clay to mold durable solid forms.

Conclusion: After extensive testing, the team discovered that up to 70% of recycled ceramic can be used in their mix.

Bravo!

Clay molds kept breaking during the initial days.

It was yet another challenge, but after a year of testing and refining the mixture’s composition, he found the perfectly balanced one.

Convincing customers about the difficulties created by ceramic waste.

Generally, people believe clay and ceramic products to be eco-friendly. It is true, but the production process of these products is far from efficient.

The Pandemic Brought an Unexpected Chance

Just as they were progressing, the COVID-19 pandemic struck, temporarily stalling development. However, this unexpected pause provided the entrepreneur with the opportunity to secure funding and successfully launch his startup.

Shashank applied for the startup grant from the Government of Gujarat. Ultimately, by the end of 2020, he received a Rs 20 lakh grant, which supported Earth Tatva for a commercial launch in 2021.

What is the Process?

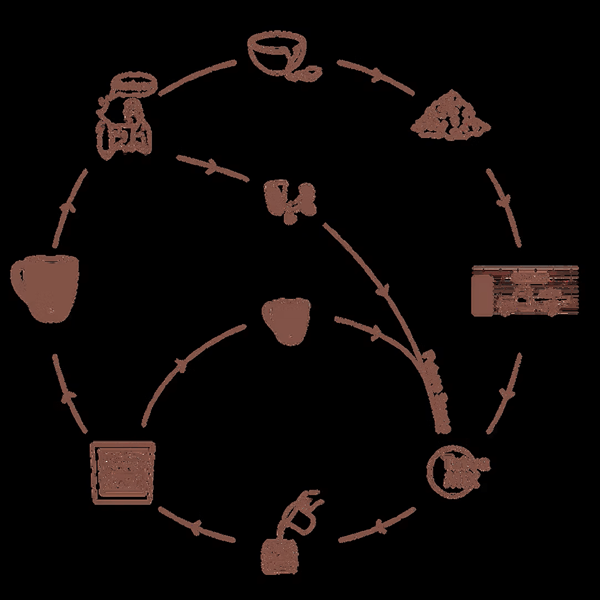

The process to convert ceramic waste into useful resources is done as follows:

- Post-industrial ceramic waste is sourced from factories in Gujarat, particularly in Morbi and Thangadh.

- Then the waste is pulverized into a fine powder.

- Next, 60% of this pulverized ceramic waste is mixed with 40% of their specially formulated clay binder.

- The mixture undergoes processing in a ball mill, ensuring a thorough blend of ingredients.

- For items such as mugs and partitions, the subsequent step is slip casting. In this process, the liquid mixture is poured into molds and left to solidify.

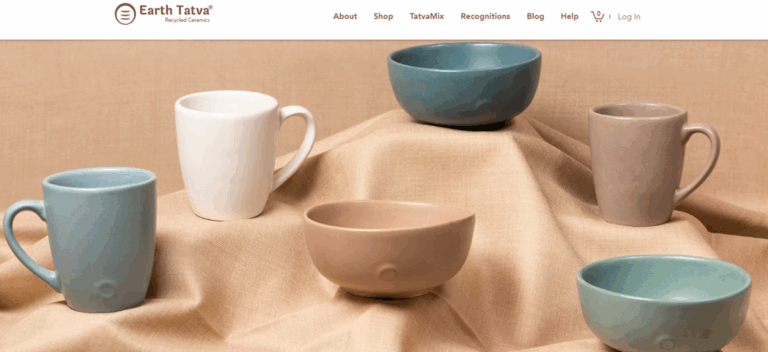

- In contrast, while producing a dough-like material for pottery, the mixture is dewatered with a filter press before being processed through a pug mill for consistent texture. This resulting blend is referred to as Tatva mix.

- Finally, reaching the desired consistency, Tatva Mix opens up a world of possibilities for artists and designers, enabling them to craft an array of products, from food bowls to tiles.

Earth Tatva by Shashank Nimkar Stays True to its Commitment to Sustainability

The startup is committed to a more sustainable, smaller-scale operation. To maintain everything on a sustainable level, the company operates on a studio level, every item is handcrafted, and none of the processes require large machinery or many workers.

This method ensures that every product is meticulously created, minimizing reliance on heavy industrial processes while also significantly lowering energy consumption compared to mass-produced ceramics.

Shashank emphasizes that the focus was not merely on creating a recycled product; the material needed to be practical for real-world design, including pottery, art, and architecture.

By recycling ceramic waste, the company has diverted about eight tonnes from landfills, saving 450-500 kg of carbon emissions. Their commitment to sustainability is evident in both products and operations.

Products are fired at 1200° C, and natural gas is used for power requirements.

Leaving a Lasting Impact

Artists, architects, studio potters, and others are now using Earth Tatva mix to make functional and artistic pieces with a lower environmental impact.

The company’s innovative partitions, crafted from recycled ceramic, are designed for dual-sided use and can be easily dismantled, ensuring they embrace a fully circular life cycle once they reach the end of their utility.

Shashank’s journey highlights how design and innovation can address environmental challenges.