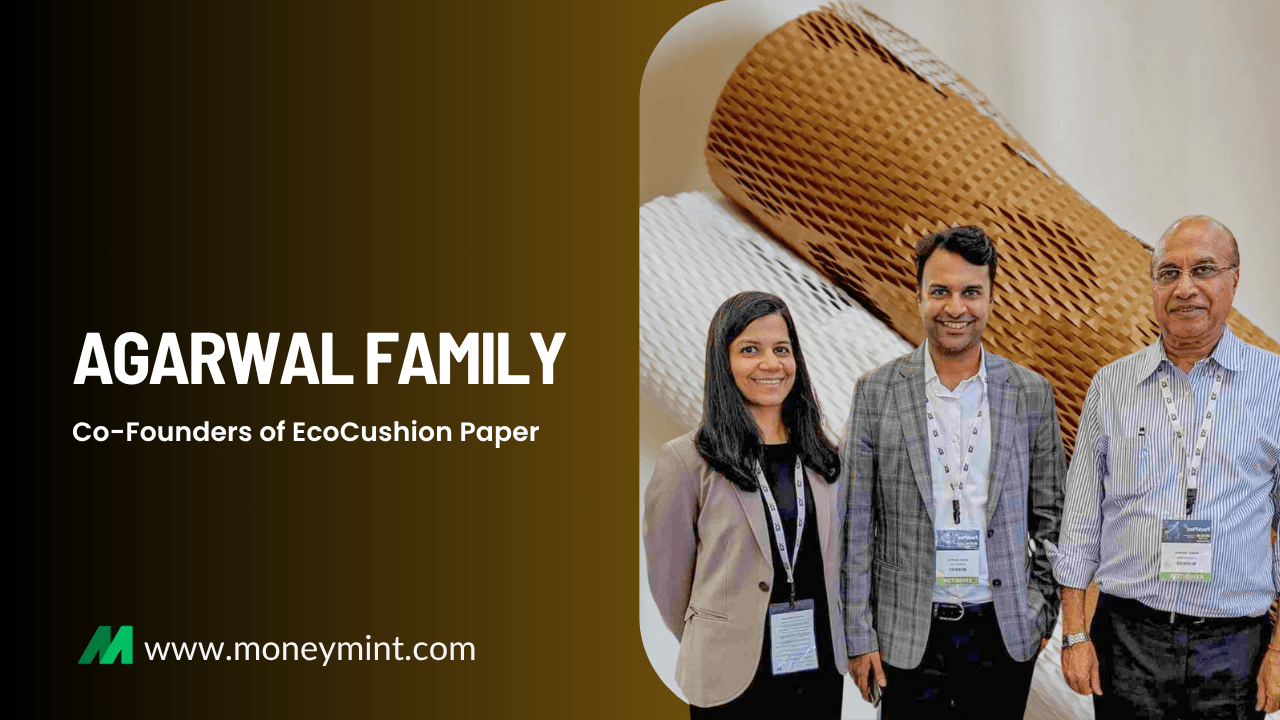

Founded in 2021 by Mahesh Agarwal, EcoCushion Paper brings sustainable alternative to single-use plastic packaging. Mahesh along with his daughter, Varsha, and son, Naman, started working on the startup when they witnessed large volume of plastic bubble wrap used for packing when they were moving from Mumbai to Delhi.

| Year | Milestones Achieved |

| 2020 | Family relocates to Mumbai; idea for EcoCushion is conceived |

| June 2021 | Official launch of EcoCushion Paper

Manufacturing set up |

| 2021-2022 | First corporate order from Westside

2,000+ SME clients onboard |

| 2022-2024 | Expanded client base (Nestle R&D, 1MG, etc.)

Achieved ₹2.5 crore revenue mark |

| 2024 | 300,000 kg of single-use plastic eliminated; strong brand advocacy |

Dedicating Time to Research and Development

Mahesh Agarwal spent six to eight months researching eco-friendly packaging solutions. Drawing on Naman’s experience in the paper industry, the family developed a honeycomb paper wrap—a recyclable, biodegradable substitute for plastic bubble wrap. Unlike most competitors who import and resell, EcoCushion established in-house manufacturing in Navi Mumbai, enabling them to serve both large and small orders, especially for SMEs.

Mission:

- To supply sustainable packaging,

- Educate businesses about the environmental impact of plastic,

- Encourage a shift to eco-friendly alternatives

Struggles, Challenges, and Solutions

#1 Setting Up During the Pandemic

The company was launched in the midst of COVID-19, which brought logistical hurdles, supply chain disruptions, and the challenge of building a team during the second wave.

#2 Changing Mindsets and Unsure Clients

Potential customers were skeptical about the products and doubted the strength and reliability of paper-based packaging. Moreover, various businesses were uncertain about switching from traditional plastic bubble wraps.

To make things easier, the team focused on educating and carried out demos to prove the product’s effectiveness.

#3 Technical Hurdles

Developing a product that matched the protective qualities of bubble wrap required extensive R&D. The team tested various parameters—paper strength, stretchability, cutting patterns for the 3D cushion effect, and overall quality—to ensure their wrap could safely protect products in transit.

#4 Market Resistance

Convincing large corporations to adopt the new solution was difficult. While many appreciated the environmental benefits, actual adoption was slow, and the team had to actively reach out and pitch to prospective clients.

Success and Growth

Despite initial resistance, EcoCushion quickly gained traction. Within a year, they had onboarded over 2,000 small and medium businesses, including notable names like Aadvik Foods, Upakarma Ayurveda, The June Shop, Mars Cosmetics, and large corporations such as Westside, Nestle R&D, and 1MG.

Unique Selling Proposition and Revenue

In-house manufacturing allows better flexibility in catering to different order sizes and makes customizations (as per client’s demand) easier.

Since its launch in June 2021, EcoCushion has generated ₹2.5 crore in revenue1. Their product pricing ranges from ₹250 for a 10-meter roll to ₹1,800 for a 250-meter roll, making it accessible for businesses of various sizes.

Brand Advocacy and Impact

Varsha Agarwal personally advocated for the product, even pitching it directly to store managers and business owners, which led to breakthrough deals like their first corporate order from Westside.

EcoCushion Paper claims to have helped eliminate nearly 300,000 kg of single-use plastic since its inception, making a significant environmental impact.

From EcoCushion’s journey we learned about the power of innovation, family entrepreneurship, and persistent advocacy for sustainability. The company was launched in a challenging environment and facing resistance to change. However, despite that, the company has built a profitable, high-impact business that is helping reshape India’s packaging industry for a greener future.